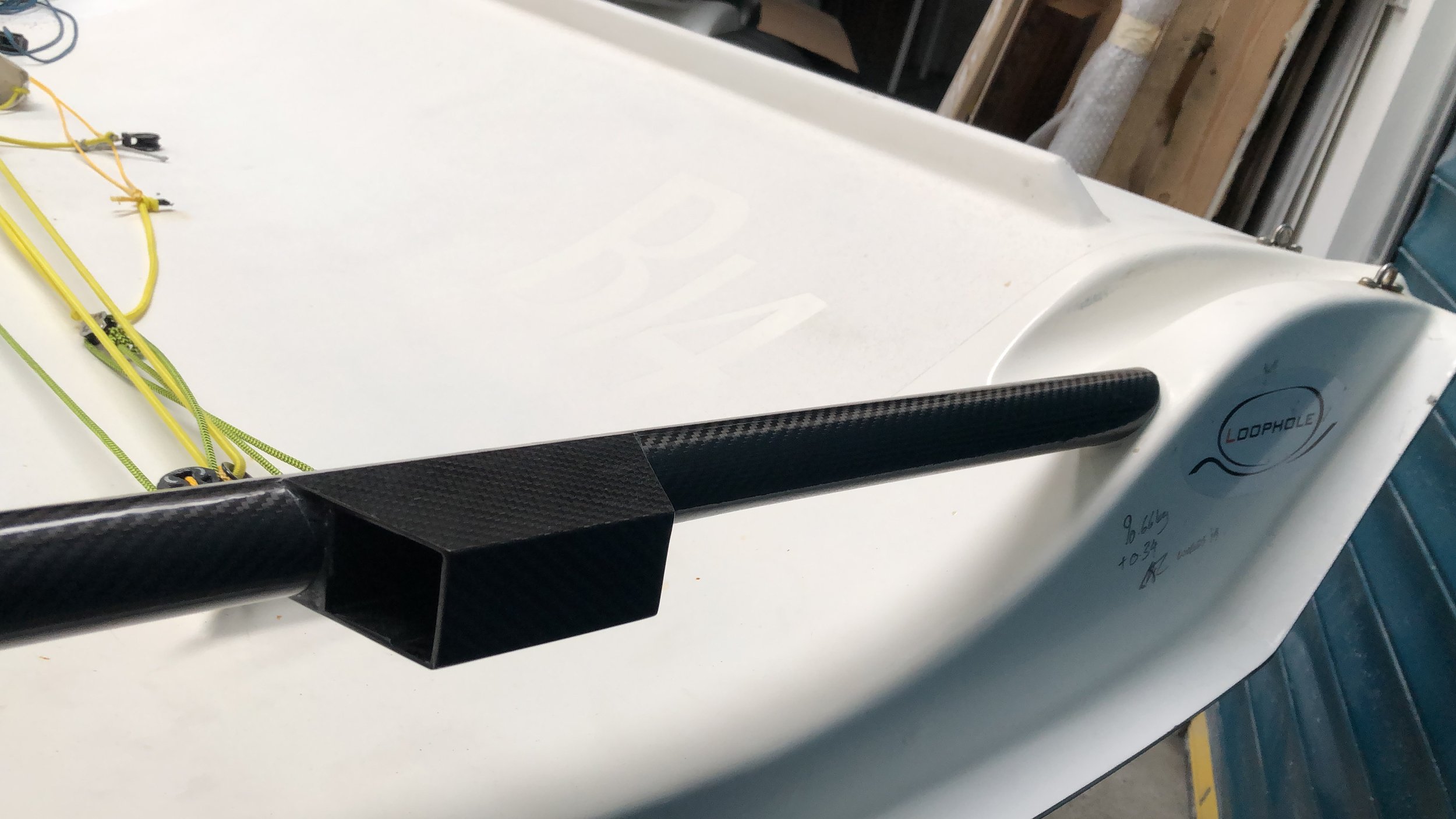

COMPOSITE Tubes

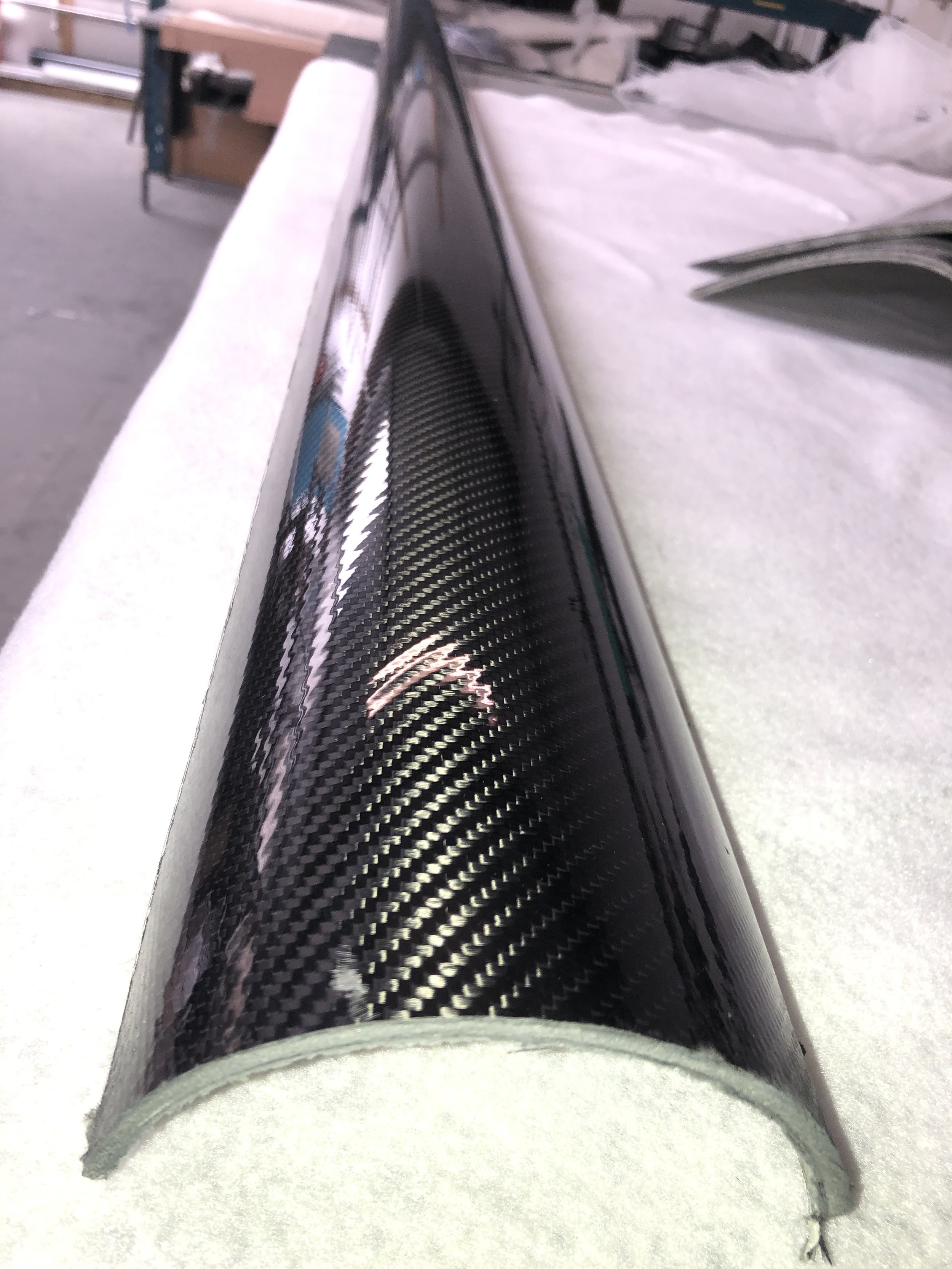

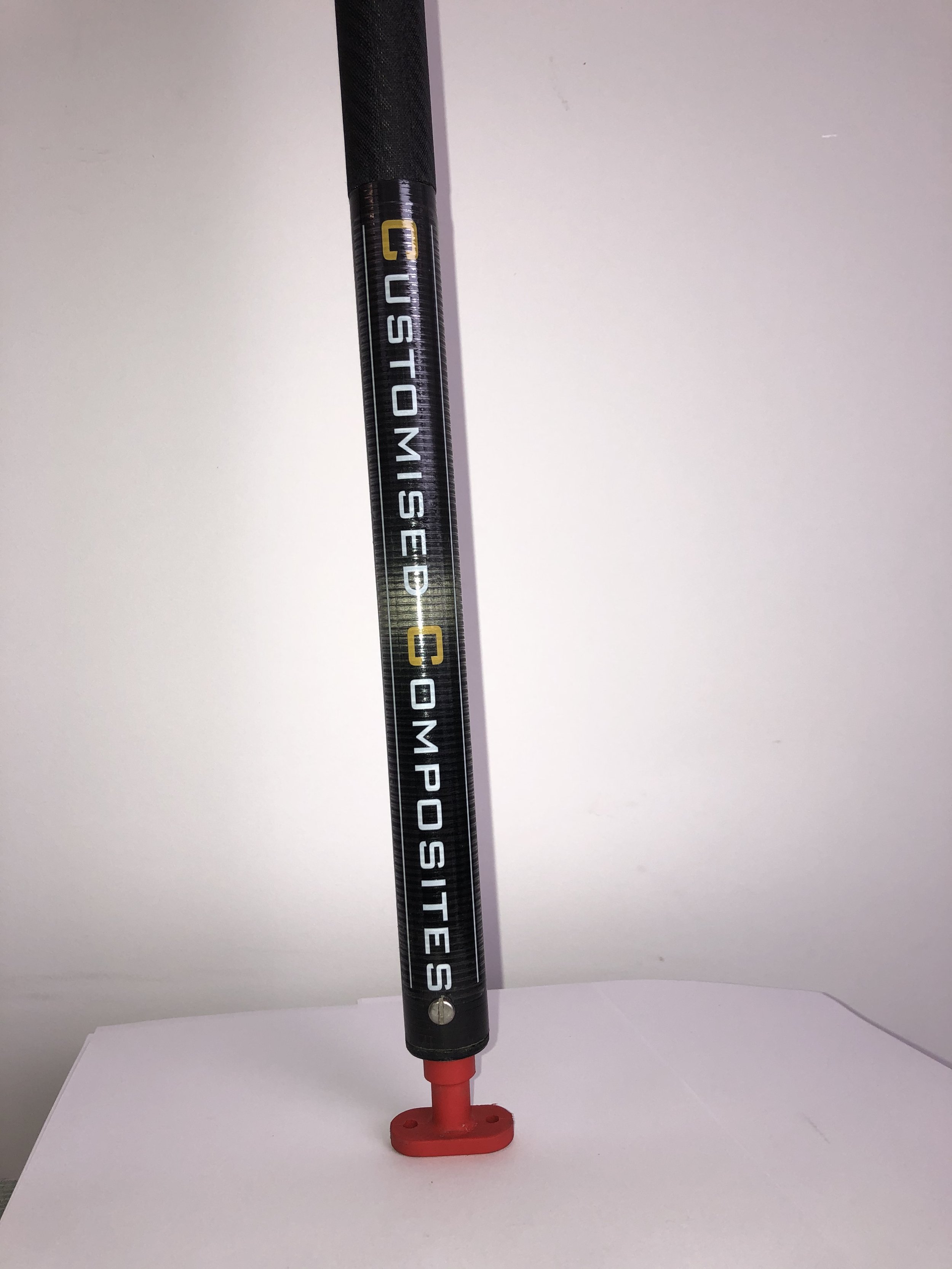

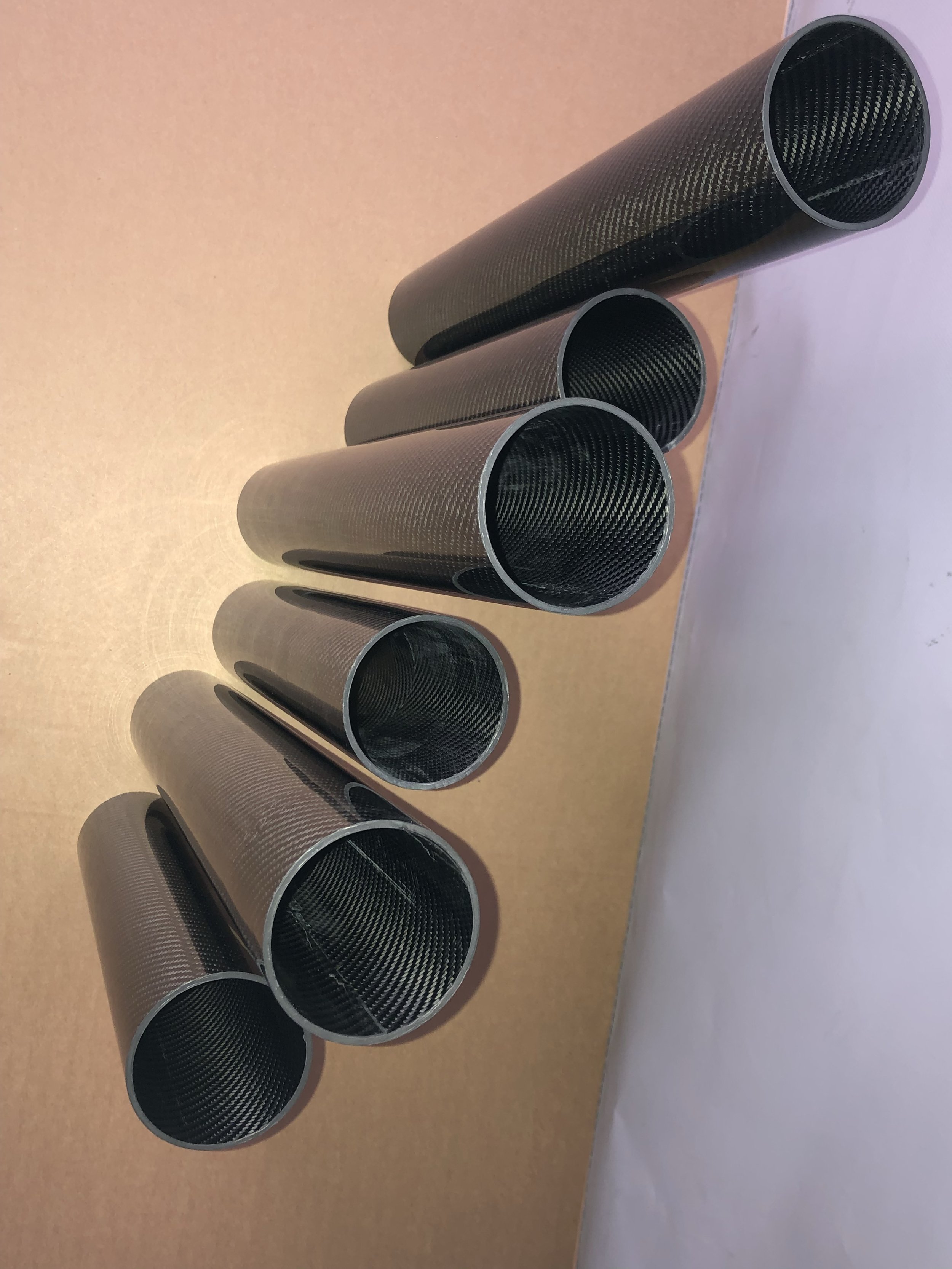

At Customised Composites we can offer a vast range of sizes, lengths and thickness’ of carbon fibre or composite tubes. Our speciality is in engineering and manufacturing bespoke tubes to meet clients specific requirements. Due to our unique manufacturing process we are able to offer almost any size of tube, without the need for expensive mandrels or female mould tools.

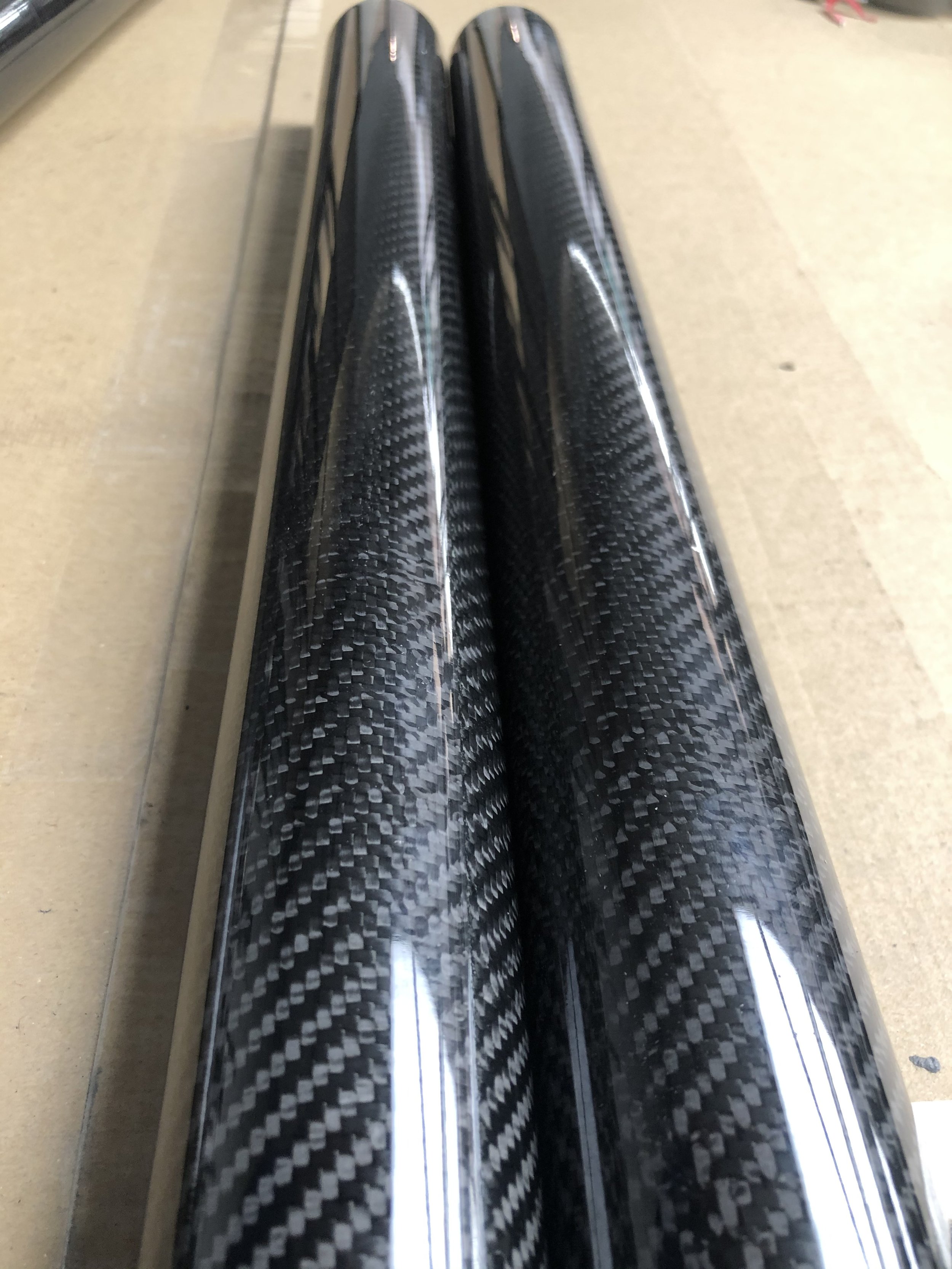

We have a range of mandrels and formers that we use to manufacture constant section and tapered tubes upto 1000mm in diameter and 5M long. We are able to achieve tollerances on ID and OD if required, we have facilities to accurately cut tubes and can offer a range of different tube finishes, from a plain (non woven) carbon finish to a fully lacquered high gloss woven finish, suitable for use in almost any environment or industry.

Using our facilities and techniques we have been able to offer tubes to a number of different companies in a number of different industries, everything from large long tubes used as spreader bars in the off-shore industry to highly accurate tubes with tight tolerances for robotics to decorative tubes, with intricately machine holes for lighting solutions.

Please contact us with your requirement or for more information.